ScaleTrains N

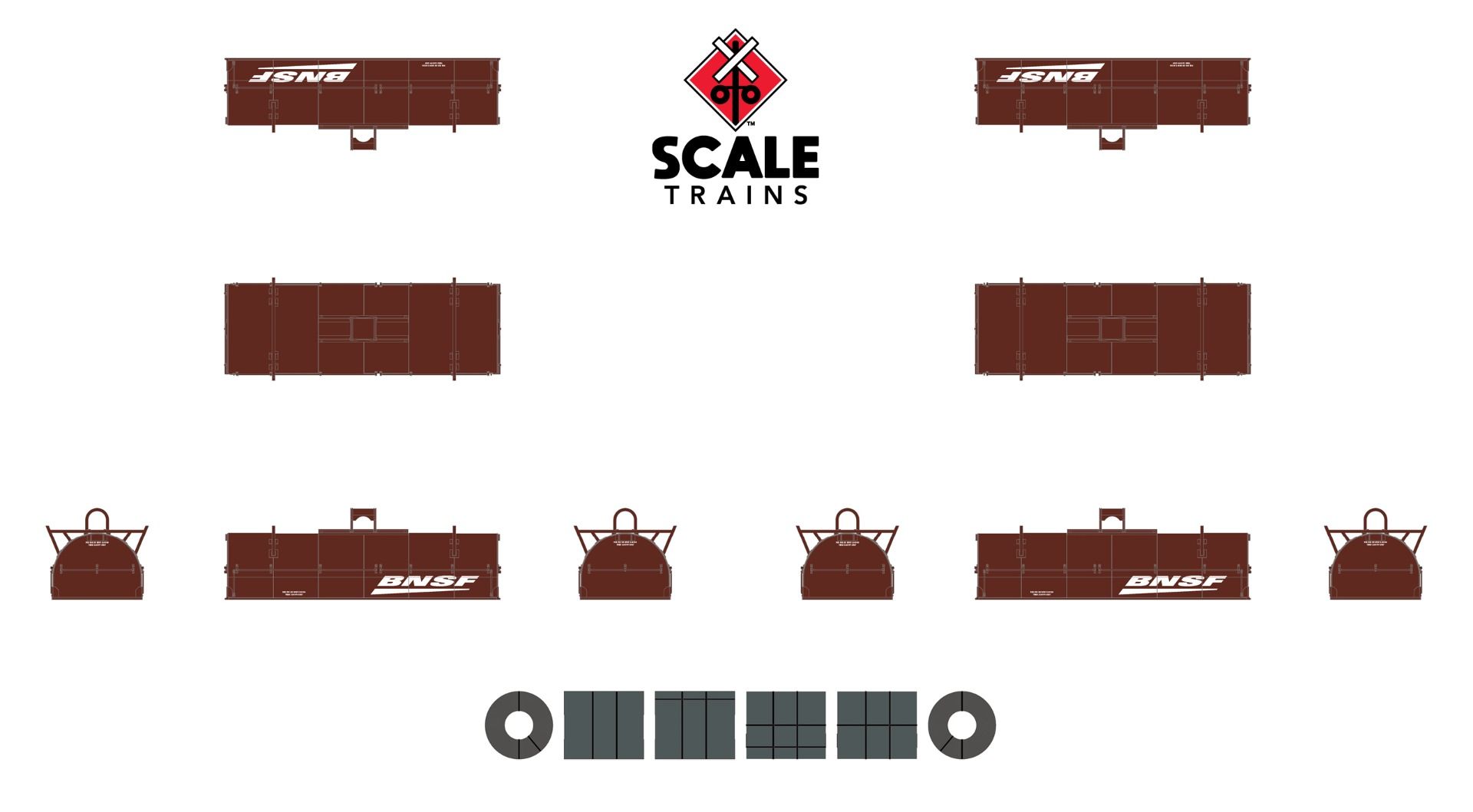

ScaleTrains Rivet Counter N SXT38639 Thrall 48' 2-Hood Coil Steel Car BNSF 'Wedge' BNSF #534110

- In Stock:

- 2

- Scale:

- N

- SKU:

- SXT38639

Description

Please note picture is representative of the item but may not be same road number. Always refer to product description for actual product details.

ScaleTrains Rivet Counter N SXT38639 Thrall 48' 2-Hood Coil Steel Car BNSF 'Wedge' BNSF #534110

Road Number Specific ScaleTrains

- All-new model

- Era: 2013 to Present

- Series 534100 to 534149; ex- ATSF 92000 to 92049, built 10-11/93

- Road numbers 534100 and 534122

- End conspicuity striping placed above end grabirons

- Side conspicuity striping centered vertically on car side

- 2 x Version 1 Hood: No corner reinforcement, long side handrail, hood stacking brackets with outer extensions

- Road numbers 534106, 534110 and 534134

- End conspicuity striping placed on end of car body

- Side conspicuity striping offset up on car side

- 2 x Version 1 Hood: No corner reinforcement, long side handrail, hood stacking brackets with outer extensions

- Road number 534147

- End conspicuity striping placed above end grabirons

- Side conspicuity striping offset up on car side

- 2 x Version 1 Hood: No corner reinforcement, long side handrail, hood stacking brackets with outer extensions

- Fully-assembled

- Multiple road numbers

- Body with dual trough design and center divider, sixteen walkway side supports and simulated wood trough interior. Designed for the use of two hoods although, depending on the type of steel, the car can be run without hoods as well.

- Body has four wireform side grab irons and four wireform end grabirons

- Each hood is constructed with up to 16 individual parts including six wireform handrails, four wireform grab irons, two hood stacking brackets, two hood top braces, and lifting bail

- Handbrake housing with finely detailed wheel and chain

- See-through photo-etched metal walkway

- Simulated wood interior floor using a hand applied wash

- Four (4) positionable load dividers

- Four (4) large unwrapped coil steel loads

- Factory-applied end handrails, hood guides, stanchions, load divider tracks, metal grab irons, coupler cut levers, and trainline hoses with silver gladhands

- Complete underbody brake system with over 15 separately applied parts including air reservoir, control valve, and retainer valve plus wireform plumbing and trainline pipe with brackets

- Body-mounted semi-scale standard Type E knuckle couplers – Micro-Trains® compatible

- ASF Ride Control trucks with finely rendered raised foundry data

- 36” machined metal wheels

- Operates on Code 55, 70 and 80 rail

- FRA-224 yellow conspicuity striping

- Printing and lettering legible even under magnification

- Paint colors match Tru-Color Paint color: TCP-199 ATSF Freight Car Red

- Weighted to Industry standards for reliable operation

- Clear jewel box packaging safely stores model

- Minimum radius: 9 ¾”

- Recommended radius: 11”

Prototype History:

Strip or sheet steel has long been a major component in the manufacturing of many different products including pipes, tanks, household appliances - both large and small, industrial shelving, machinery, freight cars, and especially automobiles. Cold-rolled or hot-rolled, varying in width from less than an inch to ten feet, and ranging in thickness from 1/64th of an inch to 1/4th of an inch, the steel was originally cut into sheets in customer specified lengths. After World War II, winding the steel strip into a coil almost completely replaced the sheets. The steel coil with 3,000 to 5,000 feet of steel is much easier to handle and transport than a stack of steel sheets. Coils are also far more versatile than a sheet that may be too long for one usage or too short for another.

The biggest challenge for railroads and the automobile industry, the primary user of coiled steel, was how to transport it efficiently. In the 1960s, the Ford Motor Company, working with the Detroit Toledo & Ironton and the Chesapeake & Ohio railroads, came up with the design of the coil steel car. The original design was a heavy-duty frame with two 24-foot troughs covered by hoods made of thin steel. The troughs and movable load dividers prevented the coils from rolling side-to-side or sliding while the hoods protected the coils from the weather. Several freight car builders built coil steel cars, including Thrall Car Manufacturing which built these 48-foot, twin hood cars in the 1980s and 1990s. The first Thrall cars had a 100-ton capacity, but later versions were built to a 125-ton capacity. Wearing the protective hoods on, the car can carry coils up to 7 feet in diameter. They can carry coils up to 10 feet with the hoods removed. The flat-top hoods from the first designs have been replaced with a rounded top design that is both easier to manufacture and is stronger.

Lombard Hobbies - Modelers helping Modelers for over 40 years!